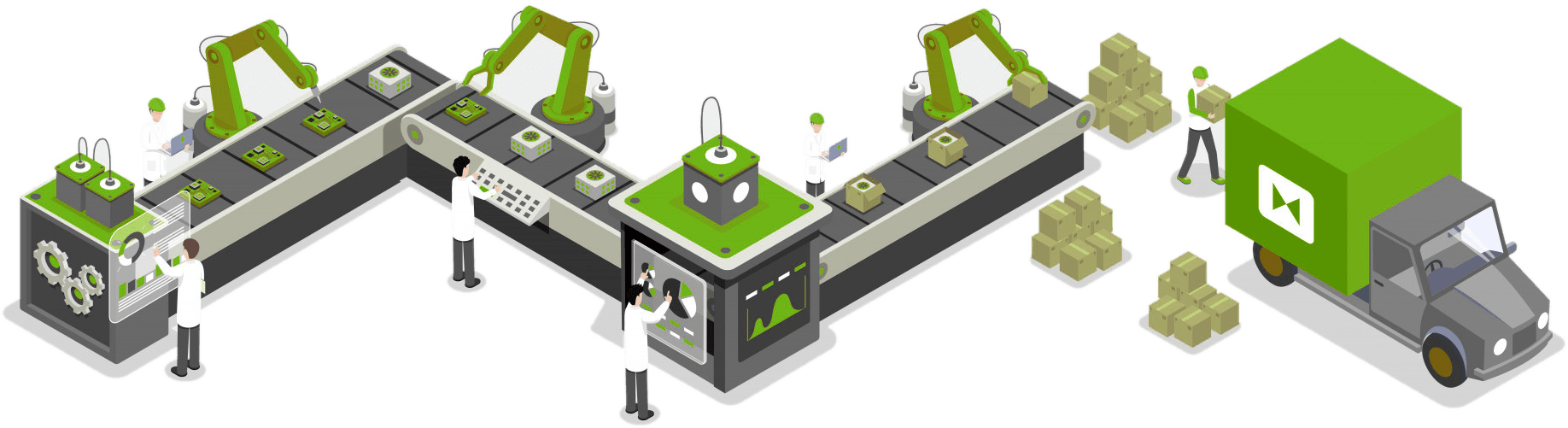

SMPL is having advanced manufacturing capabilities and processes to ensure the quality of each and every single medicine we deliver.

The state-of-the-art manufacturing facility at Kadi, about 40 Km. from Ahmedabad.

Constructed in 41,400 Sq.Ft. of land. State GMP Certified, WHO-GMP approvable, and built as per PIC/S guidelines will cater to domestic as well as international markets.

Our modern facility manufactures Tablets, Capsules Creams, Gels,Ointments, and External liquid forms catering to pharmaceuticals.

The reputation of SMPL has developed since 2021 is pure because of its Manufacturing, Quality Control, Quality Assurance, and R&D facilities to meet Ironclad quality of international standard medicines. This inspires us to furnish the best formulations and products to set a new benchmark in quality each day.

Recently India has emerged as a “Pharmacy of the World”, We have contributed our best to achieve new heights in manufacturing “Standard Quality products” to serve the overseas market.

SMPL aspires to manufacture a wide range of formulations under the observation of a highly qualified and experienced team. Our team is backed by a special Drug Development Department which is equipped with the latest technology and state-of-the-art manufacturing facilities for regional supply in India and abroad. We remain strictly adhering to the Government guidelines to execute Good Manufacturing Practice (GMP), and Good Laboratory Practice (GLP).

Premises are designed, constructed and maintained to suit the Pharma manufacturing operations as per latest cGMP norms. The layout is designed to permit effective cleaning and maintenance.

The built-up area has two floors viz. Ground floor & First floor. The ground floor comprises of Warehouse (Raw Material, Packaging Material and Finished Product) and facility to manufactures Solid Oral Dosage forms (Tablets, Hard Gelatin Capsules, Ointments, Cream, Gel & External Liquids).

- Unidirectional flow design concept integrated while building the plant.

- Well-isolated block with MAL/PAL monolithic to eliminate cross-contamination.

- Plant design complying with latest cGMP requirement as per regulatory authoritieshaving valid Drug manufacturing License No. G/25A/5726-A& G/28A/7020-A by state FDA.

- Terminal HEPA filters in manufacturing areas.

- Monolithic seamless epoxy flooring and manufacturing areas and polyurethane in secondary packaging area and finished goods.

- Water system is located onthe first floor. Ambient loop for purified water recirculation.

- Total 18 AHU and a dehumidifier for capsule area to maintain controlled temperatureand Relative Humidity. Air Changes NLT 20/ hour for the classified area. Air Recirculation with about 10% fresh air.

- Dedicated Facilities for RM/PM/FG storage.

- Processing of Products as per regulatory Guidelines.

- Own F&D facility for in-house product development.

- Own F&D facility for in-house product development.

- Zero-discharge Effluent Treatment Plant.

- Well-equipped laboratory with modern cGLP instruments.

SMPLis able to provide our customers with a wide selection of medications.In addition to herbal nutraceuticals, biological products, and injectables from a third-party manufacturer, we have a strong working relationship with a reputable pharmaceutical company.

We are dedicated to offering you the best quality product that meets international standards. We are a fully integrated organization that believes in providing quality allopathic medicines by Contract Manufacturing or Third-party manufacturing. Our rich market experience and adherence to Global standard quality helped us to reach the peak of global recognition.

You can get in touch with us if you're seeking manufacturers who specialize in integrated manufacturing. From a third party, we can manufacture items with customization.